NJoy Spirit’s Distillery is a family operated Florida whiskey distiller in the heart of the nature coast. When we started making our Rye Whiskey (we didn’t want to just make any rye) we wanted to make America’s finest original Rye Whiskey! We are confident we have achieved that and have no doubt you’ll agree with just one sip!

Wild Buck is smooth, bold, handmade and bottled at 100 proof. We start by fermenting a mash of 100% all natural home grown rye grain. We grind and cook it daily one batch at a time. We add no artificial flavorings or color and use only purified, ultraviolet filtered rain water. At NJoy Spirits our whiskey is never rushed. Our whiskey is aged in custom made new charred American Oak barrels and allowed to develop in the Florida climate. This gives our final product a deep rich flavor with a hint of spice that only develops with time using smaller barrels… the way whiskey used to be aged.

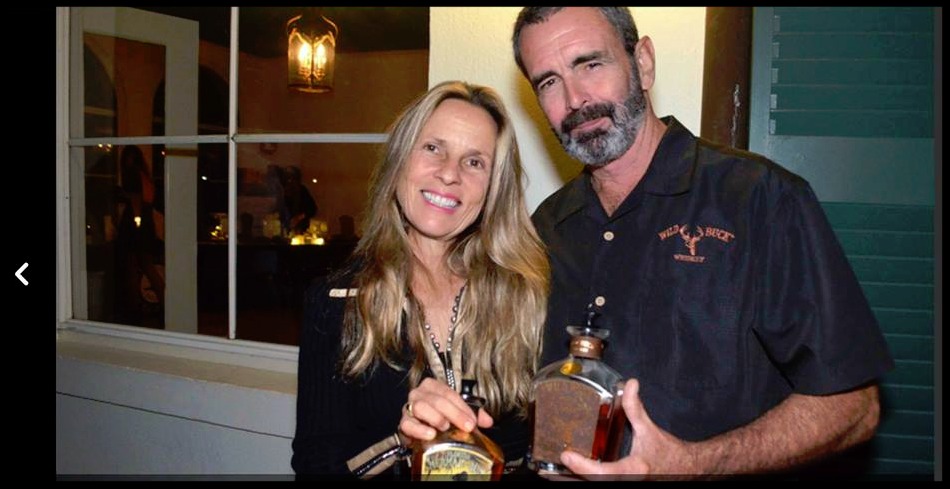

Through many years of trial and error we are very proud that our rye whiskey has become a reality! We realize patrons are the key to our success. If the liquor store you frequently visit does not carry Wild Buck Whiskey, kindly ask them to. Thanks again for your support. We are growing and would like to hear from you – please use the contact page on our website. We spoke to the founders of the distillery Natalie and Kevin Goff.

Kevin and Natalie, tell us about yourselves. What were you two involved in before getting into spirit distillation business?

Kevin and Natalie, tell us about yourselves. What were you two involved in before getting into spirit distillation business?

NG: Kevin is a Commercial Pool Designer/Contractor for over 40 years. His family has been in the Pool Business since the late 1950’s. I am a Registered Nurse.

Please tell me how the distillery came about?

KG: The 80 acre parcel was purchased in 2002 for recreational purposes. When Natalie’s father visited the property he made the remark it would make a great distillery as it was in the middle of the Chassahowitska Wildlife Management area – a 40,000 acre protected area. Natalie’s father a Scottish man – did distilling in a day but we aren’t aware he maintained a license to do so.

What have been the main challenges involved in setting up a new distillery?

What have been the main challenges involved in setting up a new distillery?

KG: The cost is tremendous. The paperwork to get started is daunting. Distillation is lengthy – but distribution (to accounts) has to be the most difficult of all.

And what has been the part you’ve enjoyed most?

KG: Meeting people who are enthusiastic about our spirits – and about the success of a small company.

What exactly does your job entail?

KG: Natalie does all the Federal and State paperwork. Sets appointments for tasting events, meets accounts in the field, accounting, ordering supplies, assist with tours, bottle washer, labeler, corker, box maker, delivery person, etc.

I am the Distiller. I take care of the entire farm – planting seed and sugar cane, grinding grain, complete distillation detail, attends events, gives tours, delivers product to distributor, orders equipment, develops spirits, etc.

What are the maturation conditions like?

KG: We have a barn on site which is open air. We palletize the various size barrels and bung hole the barrels on top. We put the barrels in the sun and rain – we also store in a warehouse barreled product where it further develops its rich color and flavor.

What whiskey expressions do you currently produce?

KG: We make Wild Buck Whiskey – which is a 100% Rye Whiskey 100 proof. 30-40% of our 401 Black Rye Grain is grown on site – the rest comes from a local farmer 20 minutes from our distillery – we also harvest our rainwater and sterilize the water twice before it’s added to our mash. Then we vat different size barrels together when we bottle (5, 15 and 25 gallon size) this creates an even finish every time. Had we pulled whiskey from 5 gallon barrels then the next time from a 25 gallon barrel the taste profile would be different – we are striving for consistency in color and taste.

Wild Buck Whiskey has won two international Gold Medals/Awards since its inception April 2015 and various international/national silver and bronze awards.

Mermaid Rum is a 3 year old 100 proof Florida Sugar Cane Rum mixed with a 25% Caribbean Pot Still Rum then finished in our once used Wild Buck Whiskey barrels for 90 days. This process has produced a great sipping rum which has earned 4 total Gold international Medals/Awards since its launch in January 2016.

Does the geographic location and the climate affect the maturation of your whiskey?

Does the geographic location and the climate affect the maturation of your whiskey?

KG: Absolutely – the hot/humid Florida climate is quite intense so we have a heavy exchange of wood with the whiskey. Further – we are get occasional freezing temperatures where we are located and this dramatic change creates the distinct flavor profile we are known for.

Do you think that your product is distinctive? If so, what makes it distinctive from other whiskies on the market?

NG: Our whiskey is created in a barn and the whiskey picks up the terroir of our estate such as: earth, leather, tobacco, cherry and chocolate which is part of the natural elements its created in. The finish is smooth for 100 proof – it does not burn on the back throat or nose as other 100 proof whiskies do. We believe this is due to our slow 16 hour steam distillation process and thru grinding fresh grain. We don’t have fancy equipment for distillation in fact most of our equipment was hand made by Kevin nearly taking him two years to complete before we ever began applying for a permit. We also use a traditional copper pot still.

Additionally, our grinder is the only automation we use. We have no bottle filler – we fill by eye. We have no bottle washer – we do that by hand and dry by hand. We label and cork by hand. F

Finally, we secure a leather strap to the bottle using needle nose plyers. Our boxes are made by a local company which we assemble on site. We load the boxes up in our pickup truck – palletize the boxes – bring the boxes down a sugar sand road 2 miles with a fork lift and then load into our truck for delivery to the distributor in Tampa. Once in Tampa the boxes are hand unloaded to a dock – ready for future delivery.

What attributes do you think are important for the Master/Head Distiller to possess?

KG: Patience, endearing work ethic, and demand for excellence. It can be a very long day using steam distillation – usually a 16 hour day – but it can even be longer. Some times for unknown reasons the yield is not as good so it can be disappointing when the final distillation is completed. Further – it would be easy to buy whiskey or rum from a huge plant (there are 7 of them in the US) and we could bottle that product like many of the distilleries do and we would probably make a whole lot of money – but for us it’s not about the money. We live modestly and enjoy our land of opportunity.

We are blessed daily to be in the woods with nature making whiskey and rum for a living. For us it’s about the life experience of creating memorable spirits people will talk about and enjoy. If one gets into the business for the money – they may be sorely mistaken as it takes years to see the benefits from years of hard labor.

Name a few other distillers or distilleries who inspire you.

Name a few other distillers or distilleries who inspire you.

KG: There are tons of great distilleries but Mill Stone in the Netherlands stands out to us – they are creating a beautiful Rye Whiskey – a bit pricey but a delight and very similar to ours.

Where or who do you feel is the driving, innovative force behind our craft distilling industry right now?

KG: Traditional spirit drinkers & food enthusiasts are demanding transparency on what they are consuming – as do the Beverage Directors that cherish “Farm to Table” menus. Our farm offers that experience. Once F&B directors visit our distillery – there is a complete transparency and trueness that sets us apart. The opportunity for a beverage director to visit – usually sets the stage for the establishment to then request our whiskey to become their house whiskey or rum. Millenniums however, are creating a strong demand for flavored products. We are hoping that this trend will dissipate and true craft whiskey and rum made traditionally will prevail. Our products do not contain artificial colors, flavorings or neutral grain spirits.

What – in your opinion – makes the spirits produced at your distillery unique?

KG: The slow distillation process – it takes us 10 days to make 20 finished gallons of product. Also, growing the grain is a huge difference we have experienced. We were buying our grain in Colorado and Canada and the bags were dated for 2 years but when opened they smelled stale and the grain was dehydrated. Daily grinding grain – the barn smells like rye bread – which is a delight. This has made all the difference in the world in our final product. The fresh sugar cane as well makes our Mermaid Rum very fragrant and deliciously smooth.

Use 3 words to describe your whiskey:

NG: Distinctive, Refined, Memorable

Is there anything else you’d like to share with our readers?

NG: We greatly appreciate the kind words of support from our whiskey and rum followers which inspires us daily to continue to hand make top quality spirits – without consumer support we could not exist and for that we are very grateful to be able to do what we do best – make whiskey & rum! Contact us in the summer for our tour schedule which will be announced on ourFacebook page and website www.wildbuckwhiskey.com